The company has more than 30 sets of vertical machining center, carving and milling machine, CNC lathe, grinder, wire cutting, electric spark, punch machine, heat treatment, sand blasting and other CNC equipment.In order to meet the different requirements of different customers, product support customized, according to customer requirements to process customized, we provide a series of comprehensive steel word stamping, steel seal engraving at the industry-leading price. Provide different grades of letter marking, alphabet stamping, steel engraving products.

Contact Now

A steel frame is a support device used in buildings and other structures, usually made of steel. They can be installed in multiple locations such as roofs, walls, floors, etc. to provide support and stability.Custom steel form brackets are designed and fabricated according to specific project requirements.

Contact Now

It is a type of medium carbon metal with excessive strength, normally used in normalizing state, and tempering therapy is used when the mechanical houses are required to be higher. Cold deformation plasticity is medium, annealing and normalizing machinability is higher than tempering.

Contact Now

A hand tapping fixture is a tool that is used to securely hold a tap and guide it during manual tapping operations. This type of fixture is commonly used in metalworking applications where precise threading is required.Hand tapping fixtures typically consist of a base that attaches to the workpiece or workbench, and a guide block that holds the tap in place at a precise angle.

Contact Now

Convex and concave mold is a special mold, mainly used to produce convex and concave shape parts, such as abrasives, plastic products, metal parts, etc., is a commonly used mold in many industries. Its function is to produce high-precision parts or products due to the need to accurately match two molds when producing products with the same convex and concave shape. The production process of convex and concave molds is generally divided into the following steps: 1.Design the shape, size and fitting principle of the two modules of convex and concave.

Contact Now

A mechanical digital combination lock is a mechanical lock that uses a digital password to open. It usually consists of a dial wheel that rotates automatically, a set of dial codes, and a mechanical device that controls the lock body. The user needs to turn the dial on the dial to the correct position in the correct order in order to open the lock.Compared with traditional key locks and electronic combination locks, mechanical digital combination locks have several advantages.

Contact Now

Steel phrase punches are used to imprint phrases or textual content onto quite a number materials, generally made from steel. They are usually made from superb hardened metal and come in a range of sizes, relying on the unique application.Here are some frequent important points and issues for metal phrase punches:Punch Size: Steel phrase punches come in a range of sizes - small, medium, and large.

Contact Now

Clamp for word roller is a kind of mechanical clamp, which is mainly composed of jaws, brackets, rollers (or balls) and adjustment devices. Among them, the jaw is the core component of Clamp for word roller, which is used to clamp the workpiece. Clamp for word roller can choose the appropriate jaw according to the shape and size of different workpieces.The advantages of Clamp for word roller have already been mentioned, its principle is similar to a scale, it can only hold the object when two places touch. Therefore, the jaws play a very important role in roller grippers.

Contact Now

Mechanical letters are a type of keyboard key that relies on mechanical switches to register keystrokes. Unlike electronic keys, which rely on a rubber dome or membrane to create an electrical connection, mechanical keys use individual switches for each key.Mechanical keys can be customized to different levels of sensitivity and provide a tactile feedback when pressed, allowing typists to feel the key being actuated.

Contact Now

A mixture of dots is a versatile and nice way to create specified and custom-made marks on metallic surfaces, presenting durability, legibility, and customization preferences for manufacturers.The blessings of the usage of a mixture of dots for metallic marking include:Customization: By the use of a mixture of dots, producers can create special and custom-made designs, logos, or textual content that stand out from ordinary marking methods.Legibility: Because dot patterns can be exactly controlled, the ensuing marks are incredibly legible and effortless to identify, even from a distance or in l

Contact Now

Simply put (machining) is the use of mechanical equipment to process materials, cutting materials, processing the required shape of the workpiece. In the whole process, the shape, size, relative position and nature of the blank form qualified parts according to the pattern and size on the drawing, which is the machining technology.Machining mainly includes manual processing and numerical control processing.

Contact Now

Mechanical letters offer a range of advantages over electronic ones, making them an attractive option for many users.Mechanical letters have a number of advantages over their electronic counterparts:Durability: Mechanical letters are more durable than electronic ones, as they are not subject to the wear and tear of electronic components such as switches or circuit boards.Tactile feedback: Mechanical letters provide a tactile feedback that is lacking in electronic letters.

Contact Now

Bent stamp products are typically metal components that have been formed through a bending process. The bending process involves using a press brake, roll bender or other industrial equipment to manipulate the shape of the metal blank so that it conforms to a specific angle or radius.The precise specifications of bent stamp products can vary widely depending on the specific application and industry in which they are used.

Contact Now

A jewelry label is a label that can be used to display information on jewelry, usually including information on brand, material, weight, origin, etc. Jewelry labels can be in different materials and forms, such as paper labels, plastic labels, metal labels, silk labels, etc., and can be processed by printing, engraving, hot stamping and other techniques.The main role of jewelry labels is to provide more jewelry information, so that consumers can better understand the characteristics and value of this jewelry.

Contact Now

Steel Star perforated stamps are a special type of stamp whose design is inspired by the perforated technique of pen nibs commonly used in the fields of paper, bank notes, credit cards, etc. These stamps have one or more holes the size and shape of pen nibs on the front and back.Steel Star perforated stamps are a type of stamp that is difficult to counterfeit because the holes are of various shapes and cannot be copied easily. Also, since the stamp is made of high-quality steel, it is extremely durable and less prone to wear and damage.

Contact Now

Arc stamping, also known as electric arc stamping or spark stamping, is a metalworking process that involves using an electric arc to create intricate designs, lettering, or patterns on metal surfaces. Here are some details about the arc stamping process:Principle: Arc stamping uses an electric arc between an electrode and the workpiece to heat and vaporize the target material, creating a controlled spark or arc that engraves or marks the surface of the metal.Equipment: The primary components of an arc stamping system include a power source, an electrode, and a workpiece holder.

Contact Now

A roller wheel, also known as a rotary stamp wheel or rotating wheel stamp, is a cylindrical tool used for marking or labeling purposes. Here are some details about the roller wheel:Construction: A roller wheel typically consists of a cylindrical body with individual characters, symbols, or numbers engraved or embossed on its surface.

Contact Now

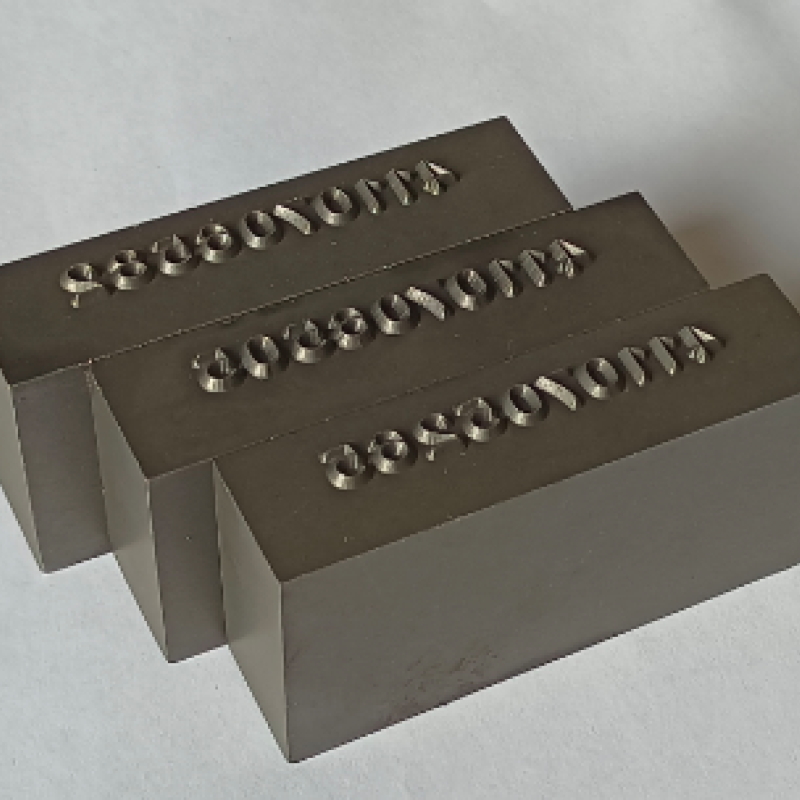

CNC stamp engraving is a technology that uses a CNC engraving machine to engrave designs or patterns on stamps. Stencil customization and quenching process are two concepts related to this process. Here's an explanation of this information:CNC stamp engraving: CNC (Computer Numerical Control) stamp engraving uses a computer-controlled machine to engrave designs or patterns. This technology can accurately carve intricate details and exquisite patterns on steel stamps.

Contact Now

A punctate metal mark is a kind of marking technique that includes the use of a collection of carefully spaced dots or small impressions to create a clear and everlasting mark on a metal surface. This method is normally used for developing section numbers, identification marks, serial numbers or other sorts of labeling on steel factors and parts.Punctate metal marking can be carried out the usage of a variety of techniques, such as dot peen marking machines, laser engraving structures or electrochemical etching machines.

Contact Now

Leather stamps are used to imprint designs or patterns onto leather material. They are typically made from heavy-duty metal and come in a variety of shapes and sizes, depending on the specific application.As a leather stamp manufacturer with 30 years of processing experience, we know the importance of every detail for product quality and customer satisfaction. We are committed to providing various types of leather stamps, including eco-friendly leather stamps, PU leather stamps, leather stamps and so on.

Contact Now

A custom leather stamp is a tool used to imprint designs, logos or text onto a variety of leather goods such as bags, wallets, belts, and other accessories. These stamps are typically made from metal and feature raised letters, symbols, or designs that create an indentation when pressed into the leather surface.The customization process for a leather stamp involves working with a manufacturer or supplier to create a stamp with your desired design or text.

Contact Now

Handheld stamps for leather-based are specialised steel stamps used to create permanent, stamped impressions onto leather. These stamps are normally held and used with the aid of hand, as an alternative than being installed onto a press or different machinery.Handheld stamps can be used to create a broad vary of designs consisting of letters, numbers, logos, and different patterns that can be used to customise and customize leather-based goods.

Contact Now

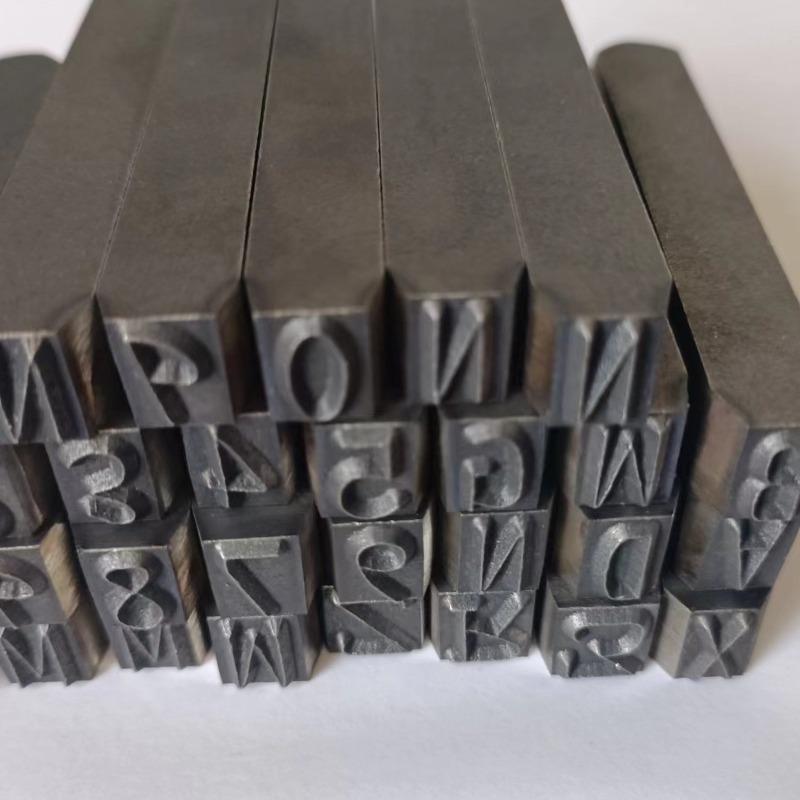

Alphabet stamps are tools used to imprint text or designs onto materials such as paper, leather, fabric, and metal. They consist of a set of individual stamps that have raised letters, numbers, or symbols on their faces, which can be arranged in different combinations to create words, phrases, or designs.Alphabet stamps come in different sizes, fonts, and styles, ranging from basic block letters to more decorative script styles.

Contact Now

Jewelry design stamps is a professional manufacturer of steel stamps. Our company Jewelry, as one of the products of people's pursuit of beauty, has been concerned and sought after. And jewelry design stamp, is used to mark jewelry on an important tool.Jewelry design stamps can be traced back to the early history of stamp design, which was originally designed to mark jewelry items with information such as material, weight, grade, finish, etc.

Contact Now