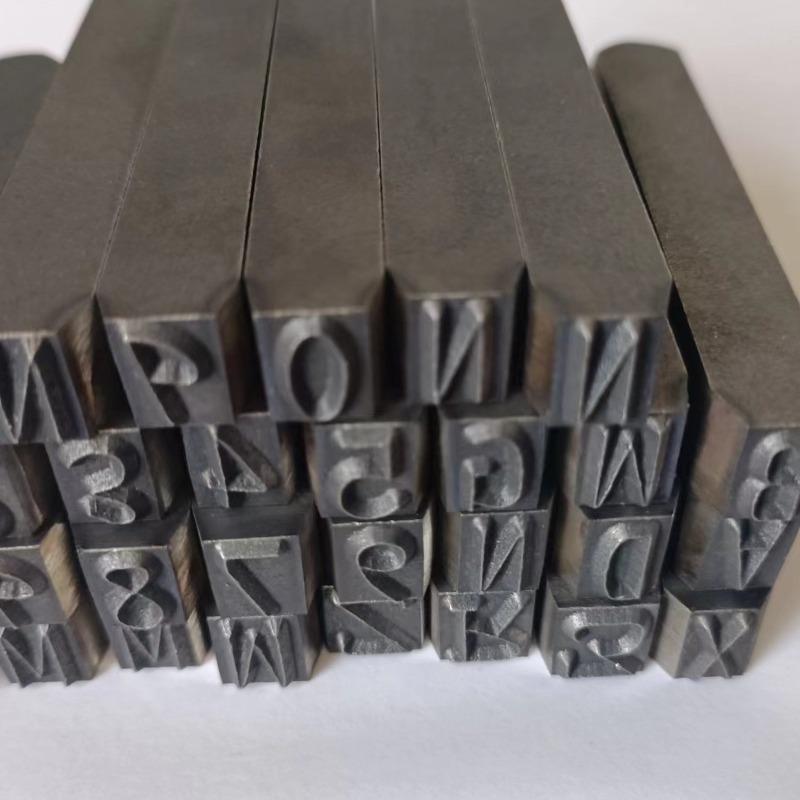

A low-stress letter is a type of letter marking method used to create clear and legible imprints on metal surfaces without causing damage or stress to the material. This technique involves using a low-impact marking method that reduces the amount of force and pressure applied to the metal surface, preventing cracking, deformation, or other types of damage.There are several low-stress letter marking techniques available, including dot peen marking, laser engraving, and electrochemical etching.

Contact Now

Low stress refers to a method or technique that reduces the amount of force or impact applied to an object or material, resulting in less damage or stress to the material. This can be particularly important when working with sensitive materials or components that need to maintain their integrity.In the context of metalworking and manufacturing, low-stress techniques are used to prevent cracking, deformation, or other types of damage to metal surfaces during the marking, engraving, or stamping process.

Contact Now

The low-stress steel code is a special type of steel code, the main feature of which is the ability to maintain a low stress level during use. This makes low-stress steel codes excellent in a wide range of applications, especially where high strength, low stress and durability are required.Low-stress steel fonts are also widely used in machinery manufacturing, mold making, and logo making. In the process of machinery manufacturing, low-stress steel font codes can be used to mark information about various equipment, parts, and products, such as name, model, specification, etc.

Contact Now

Low stress figure OEM refers to an original equipment manufacturer that specializes in creating precise and clear imprints on metal surfaces using low-impact marking methods. Their machinery, processes, and techniques are designed to minimize the amount of force and pressure applied to the metal surface, reducing the risk of damage or deformation.Low stress figure OEMs typically use specialized equipment such as dot peen marking machines, laser engraving systems, or electrochemical etching machines to create high-quality marks on metal surfaces.

Contact Now

Low-stress steel marking is a technique used to imprint text or designs onto metal surfaces, such as pipes, tanks, and equipment, without causing damage to the material. This is achieved by using a low-impact marking method that reduces stress on the metal, preventing cracking or deformation.There are several techniques used for low-stress steel marking, including dot peen marking, laser engraving, and electrochemical etching. Dot peen marking is a process where a series of small dots are stamped onto the metal surface in a specific pattern to create the desired text or design.

Contact Now

Low stress steel fonts are designed for use with metal stamping and marking applications where there is a risk of stress or deformation in the material being stamped.

Contact Now

A handheld low-stress steel word stamp is a type of stamp that is used to imprint words or text onto various materials, typically made from steel. These stamps are designed to be held by hand and applied with moderate pressure, using a hammer or mallet to create the impression.Here are some details and considerations for this type of product:Material: The steel used in these stamps is typically hardened to resist wear and tear, ensuring longevity and consistent performance.Size and Font: Handheld low-stress steel word stamps come in various sizes and font styles.

Contact Now

Custom low-stress stamps are tools used for marking various surfaces with a particular design or text. These stamps are designed to minimize the amount of pressure required to create an impression, making them ideal for repetitive stamping tasks that can cause hand fatigue.These stamps are typically made from polymer materials such as rubber, silicone or photopolymer. The design is etched onto the stamp with a laser or photoengraving process.

Contact Now

Low Stress Round-Face Number Stamp Sets is a stamp made using high-end precision die steel, which is usually used in fields such as aerospace, nuclear industry and oil industry. This type of stamp uses advanced production processes and materials to ensure a high degree of precision, durability and reliability.Precision die steel is a steel with high hardness, excellent corrosion resistance, high temperature stability and precision machining capability.

Contact Now

The company has more than 30 sets of vertical machining center, carving and milling machine, CNC lathe, grinder, wire cutting, electric spark, punch machine, heat treatment, sand blasting and other CNC equipment.In order to meet the different requirements of different customers, product support customized, according to customer requirements to process customized, we provide a series of comprehensive steel word stamping, steel seal engraving at the industry-leading price. Provide different grades of letter marking, alphabet stamping, steel engraving products.

Contact Now

Metal craft punching letters, also known as metal letter punches or metal letter stamps, are specialized tools used for imprinting letters onto metal surfaces. These tools are commonly used in various crafts, such as jewelry making, leatherwork, metalworking, and other DIY projects.Metal craft punching letters typically consist of individual letter stamps made from hardened and durable metals, such as steel or brass. Each stamp features a raised letter on one end and has a handle or shaft for gripping and applying pressure.

Contact Now

A letter stamp punch set is a device used to imprint character letters onto a range of materials, such as metal, leather, and wood. The set normally consists of a choice of steel stamps that have the letters of the alphabet engraved on their faces, as nicely as numbers and some punctuation marks.The stamps can be made from a number materials, such as metal or brass, and can also have a hardened floor to make certain durability.

Contact Now

Tempered letter stamping is a metalworking technique where steel stamps are heat-treated to increase their durability and hardness. This process involves heating the stamps to a specific temperature and then rapidly cooling them, often in oil or water. This cooling process, known as quenching, helps to harden the stamps, making them more resistant to wear and capable of consistently creating clean and crisp letter impressions on various materials. After quenching, the stamps are often further tempered to reduce brittleness and increase toughness.

Contact Now

Steel phrase punches are used to imprint phrases or textual content onto quite a number materials, generally made from steel. They are usually made from superb hardened metal and come in a range of sizes, relying on the unique application.Here are some frequent important points and issues for metal phrase punches:Punch Size: Steel phrase punches come in a range of sizes - small, medium, and large.

Contact Now

Our companyQihe Ruifeng Steel Letter Engraving Co.,Ltd. was established in 2012, is located in Qihe County Development Zone, Dezhou City, Shandong Province, Zongchuang Industrial Park in a convenient location. Is a company with 30 years of professional engraving production.Alphabet stampis a tool used to mark a weld, usually made of a high-strength alloy material. It can print relevant information on the weld, such as welding date, welder number, welding material lot number, etc.

Contact Now

A knurling tool is a cutting tool that can be used to make various concave and convex patterns on metal surfaces. They usually consist of a cylindrical head and a treaded wheel.When using a knurling tool, the workpiece is first held on a rotating table.

Contact Now

A steel frame is a support device used in buildings and other structures, usually made of steel. They can be installed in multiple locations such as roofs, walls, floors, etc. to provide support and stability.Custom steel form brackets are designed and fabricated according to specific project requirements.

Contact Now

Holding jewelry stamps are useful tools for jewelry makers and metalworkers who need to imprint designs or patterns onto small metal objects. By providing stability and support for the stamp during use, these tools help ensure accurate and consistent results.Here are some common details and considerations for holding jewelry stamps:Material: Holding jewelry stamps can be made from a variety of materials, including hard plastic, wood, or metal.

Contact Now

A punctate steel mark (PSM) is a type of marking method used to create a clear and permanent indent or impression on metal surfaces. This technique involves using a series of closely spaced dots or small impressions, rather than continuous lines, to form the desired text or design.Punctate steel marking is often used in industries such as aerospace, automotive, and military, where manufacturers need to create durable and legible marks on metal components and parts.

Contact Now

A custom steel grade is a steel that is designed and produced according to a customer's specific needs and requirements. Usually, these requirements include requirements for the use of materials, environment, strength, hardness, etc. Compared with standard steel, customized steel has more precise property matching, higher quality controllability and higher production efficiency.In the production process of customized steel grades, it is first necessary to understand the needs of customers, including steel usage, specifications, production batch quantities, delivery time, etc.

Contact Now

Mechanical letters are a type of keyboard key that relies on mechanical switches to register keystrokes. Unlike electronic keys, which rely on a rubber dome or membrane to create an electrical connection, mechanical keys use individual switches for each key.Mechanical keys can be customized to different levels of sensitivity and provide a tactile feedback when pressed, allowing typists to feel the key being actuated.

Contact Now

Mechanical letters are a type of keyboard key that relies on mechanical switches to register keystrokes. Unlike electronic keys, which rely on a rubber dome or membrane to create an electrical connection, mechanical keys use individual switches for each key.Mechanical keys can be customized to different levels of sensitivity and provide a tactile feedback when pressed, allowing typists to feel the key being actuated.

Contact Now

Mechanical letters are a type of keyboard key that relies on mechanical switches to register keystrokes. Unlike electronic keys, which rely on a rubber dome or membrane to create an electrical connection, mechanical keys use individual switches for each key.Mechanical keys can be customized to different levels of sensitivity and provide a tactile feedback when pressed, allowing typists to feel the key being actuated.

Contact Now

A scroll wheel is a small, cylindrical component located between the left and right buttons on a computer mouse. It allows users to scroll through content on their screen without having to drag the page up or down manually. When the user rolls the wheel forward or backward, it sends signals to the computer, which in turn scrolls the content up or down.Scroll wheels were first introduced by Microsoft in 1996 as part of their IntelliMouse line of computer mice.

Contact Now