Low stress refers to a method or technique that reduces the amount of force or impact applied to an object or material, resulting in less damage or stress to the material. This can be particularly important when working with sensitive materials or components that need to maintain their integrity.In the context of metalworking and manufacturing, low-stress techniques are used to prevent cracking, deformation, or other types of damage to metal surfaces during the marking, engraving, or stamping process.

Contact Now

The low-stress steel code is a special type of steel code, the main feature of which is the ability to maintain a low stress level during use. This makes low-stress steel codes excellent in a wide range of applications, especially where high strength, low stress and durability are required.Low-stress steel fonts are also widely used in machinery manufacturing, mold making, and logo making. In the process of machinery manufacturing, low-stress steel font codes can be used to mark information about various equipment, parts, and products, such as name, model, specification, etc.

Contact Now

Low stress figure OEM refers to an original equipment manufacturer that specializes in creating precise and clear imprints on metal surfaces using low-impact marking methods. Their machinery, processes, and techniques are designed to minimize the amount of force and pressure applied to the metal surface, reducing the risk of damage or deformation.Low stress figure OEMs typically use specialized equipment such as dot peen marking machines, laser engraving systems, or electrochemical etching machines to create high-quality marks on metal surfaces.

Contact Now

A low-stress letter is a type of letter marking method used to create clear and legible imprints on metal surfaces without causing damage or stress to the material. This technique involves using a low-impact marking method that reduces the amount of force and pressure applied to the metal surface, preventing cracking, deformation, or other types of damage.There are several low-stress letter marking techniques available, including dot peen marking, laser engraving, and electrochemical etching.

Contact Now

Low-stress steel marking is a technique used to imprint text or designs onto metal surfaces, such as pipes, tanks, and equipment, without causing damage to the material. This is achieved by using a low-impact marking method that reduces stress on the metal, preventing cracking or deformation.There are several techniques used for low-stress steel marking, including dot peen marking, laser engraving, and electrochemical etching. Dot peen marking is a process where a series of small dots are stamped onto the metal surface in a specific pattern to create the desired text or design.

Contact Now

Low stress steel fonts are designed for use with metal stamping and marking applications where there is a risk of stress or deformation in the material being stamped.

Contact Now

A handheld low-stress steel word stamp is a type of stamp that is used to imprint words or text onto various materials, typically made from steel. These stamps are designed to be held by hand and applied with moderate pressure, using a hammer or mallet to create the impression.Here are some details and considerations for this type of product:Material: The steel used in these stamps is typically hardened to resist wear and tear, ensuring longevity and consistent performance.Size and Font: Handheld low-stress steel word stamps come in various sizes and font styles.

Contact Now

Custom low-stress stamps are tools used for marking various surfaces with a particular design or text. These stamps are designed to minimize the amount of pressure required to create an impression, making them ideal for repetitive stamping tasks that can cause hand fatigue.These stamps are typically made from polymer materials such as rubber, silicone or photopolymer. The design is etched onto the stamp with a laser or photoengraving process.

Contact Now

Low Stress Round-Face Number Stamp Sets is a stamp made using high-end precision die steel, which is usually used in fields such as aerospace, nuclear industry and oil industry. This type of stamp uses advanced production processes and materials to ensure a high degree of precision, durability and reliability.Precision die steel is a steel with high hardness, excellent corrosion resistance, high temperature stability and precision machining capability.

Contact Now

A punctate metal mark is a kind of marking technique that includes the use of a collection of carefully spaced dots or small impressions to create a clear and everlasting mark on a metal surface. This method is normally used for developing section numbers, identification marks, serial numbers or other sorts of labeling on steel factors and parts.Punctate metal marking can be carried out the usage of a variety of techniques, such as dot peen marking machines, laser engraving structures or electrochemical etching machines.

Contact Now

A mixture of dots is a versatile and nice way to create specified and custom-made marks on metallic surfaces, presenting durability, legibility, and customization preferences for manufacturers.The blessings of the usage of a mixture of dots for metallic marking include:Customization: By the use of a mixture of dots, producers can create special and custom-made designs, logos, or textual content that stand out from ordinary marking methods.Legibility: Because dot patterns can be exactly controlled, the ensuing marks are incredibly legible and effortless to identify, even from a distance or in l

Contact Now

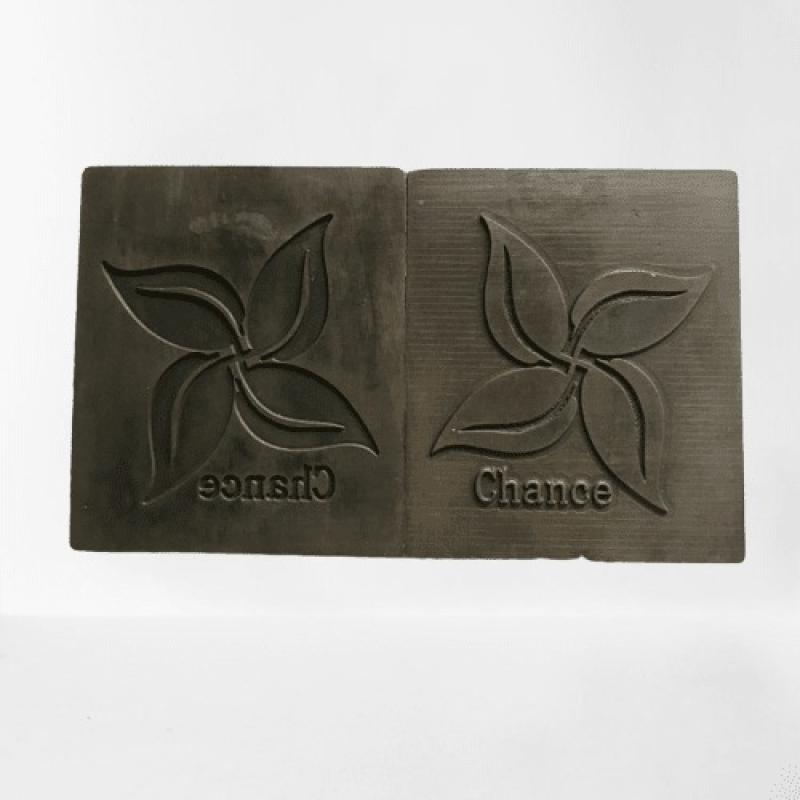

CNC stamp engraving is a technology that uses a CNC engraving machine to engrave designs or patterns on stamps. Stencil customization and quenching process are two concepts related to this process. Here's an explanation of this information:CNC stamp engraving: CNC (Computer Numerical Control) stamp engraving uses a computer-controlled machine to engrave designs or patterns. This technology can accurately carve intricate details and exquisite patterns on steel stamps.

Contact Now

A custom leather stamp is a tool used to imprint designs, logos or text onto a variety of leather goods such as bags, wallets, belts, and other accessories. These stamps are typically made from metal and feature raised letters, symbols, or designs that create an indentation when pressed into the leather surface.The customization process for a leather stamp involves working with a manufacturer or supplier to create a stamp with your desired design or text.

Contact Now

A custom leather stamp is a specialized metal stamp that is used to imprint designs, letters, or logos onto leather products. The stamp can be used to create unique branding, personalization, or customization on a wide range of leather goods including wallets, belts, bags, and more.Custom leather stamps can be highly personalized, with a range of options available including font styles, sizing, and logo or graphic design.

Contact Now

In a competitive market environment, it is not easy to survive and successfully run a business for 11 years. And such an enterprise is an old enterprise focusing on customized metal seals. Their experience and strength make us the leader in the industry.As a professional metal stamp customization enterprise, its products not only have the characteristics of high quality, more importantly, they are widely used in various fields, such as steel products, auto parts, jewelry, leather and so on.

Contact Now

Clamp for word roller is a kind of mechanical clamp, which is mainly composed of jaws, brackets, rollers (or balls) and adjustment devices. Among them, the jaw is the core component of Clamp for word roller, which is used to clamp the workpiece. Clamp for word roller can choose the appropriate jaw according to the shape and size of different workpieces.The advantages of Clamp for word roller have already been mentioned, its principle is similar to a scale, it can only hold the object when two places touch. Therefore, the jaws play a very important role in roller grippers.

Contact Now

A custom handheld device is a mobile device that can be designed and manufactured according to the specific needs and requirements of customers, usually including hardware, software, operating system, etc.

Contact Now

Leather stamps are used to imprint designs or patterns onto leather material. They are typically made from heavy-duty metal and come in a variety of shapes and sizes, depending on the specific application.As a leather stamp manufacturer with 30 years of processing experience, we know the importance of every detail for product quality and customer satisfaction. We are committed to providing various types of leather stamps, including eco-friendly leather stamps, PU leather stamps, leather stamps and so on.

Contact Now

Plate stamps for metal are used to imprint designs or patterns onto metal plates, typically made from steel. They are typically made from high-quality tool steel and come in a variety of shapes and sizes, depending on the specific application.Here are some common details and considerations for plate stamps for metal:Stamp Size: Plate stamps come in various sizes - small, medium, and large.

Contact Now

Whether your product is metal, wood, leather, embellishes or plastic etc., we have an skilled crew geared up to produce your customized sheet metal stamps with precision and detail. When you desire to repeat an picture or layout alongside leather-based strips such as belts, we will produce excessive first-rate brass or metal roll molds to your specs to go well with your roll marking desktop or for guide use. There's nothing extra incredible than a appropriate LOGO stencil.

Contact Now

Mechanical letters offer a range of advantages over electronic ones, making them an attractive option for many users.Mechanical letters have a number of advantages over their electronic counterparts:Durability: Mechanical letters are more durable than electronic ones, as they are not subject to the wear and tear of electronic components such as switches or circuit boards.Tactile feedback: Mechanical letters provide a tactile feedback that is lacking in electronic letters.

Contact Now

A machine fixture is a specialized tool used to securely hold a workpiece in place during machining operations.

Contact Now

Construction: Hand punch combination molds are typically made of high-quality steel or other durable materials to ensure longevity and precision in creating detailed designs.Versatility: These molds come in various shapes and sizes, and they may include multiple punch heads to allow for a variety of design options.

Contact Now

Mechanical steel stamping, also known as metal stamping or steel marking, is a common method of product identification. It involves using a machine to engrave designs or text onto metal, plastic, rubber, or other materials. The process typically uses a hardened alloy or high-speed steel stamp that is pressed into the surface of the material, leaving a permanent impression.Mechanical steel stamping is a versatile and durable method of marking products, and it has many advantages over other identification methods.

Contact Now