Low stress refers to a method or technique that reduces the amount of force or impact applied to an object or material, resulting in less damage or stress to the material. This can be particularly important when working with sensitive materials or components that need to maintain their integrity.In the context of metalworking and manufacturing, low-stress techniques are used to prevent cracking, deformation, or other types of damage to metal surfaces during the marking, engraving, or stamping process.

Contact Now

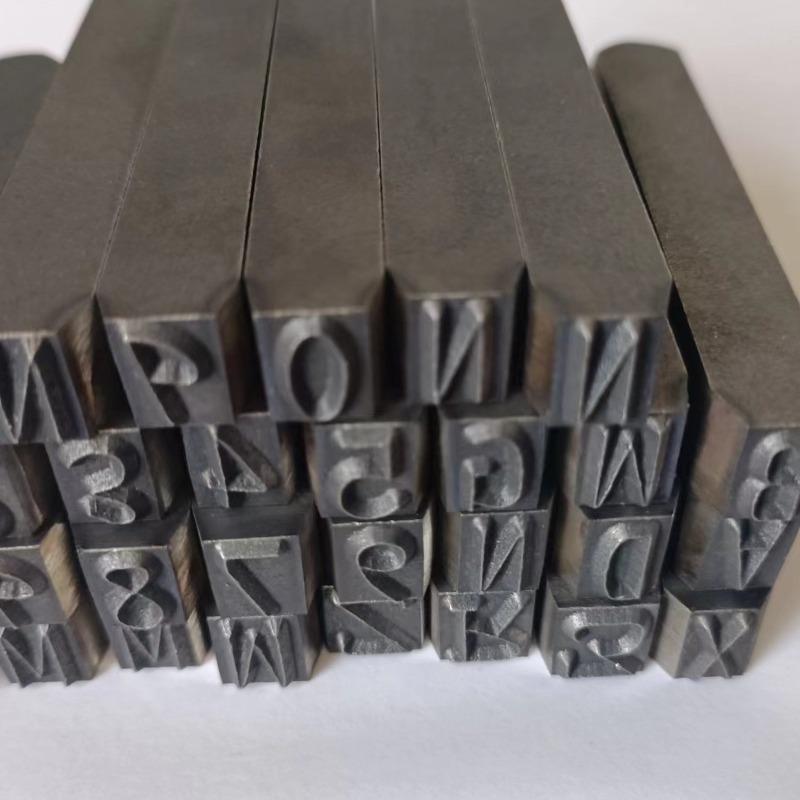

The low-stress steel code is a special type of steel code, the main feature of which is the ability to maintain a low stress level during use. This makes low-stress steel codes excellent in a wide range of applications, especially where high strength, low stress and durability are required.Low-stress steel fonts are also widely used in machinery manufacturing, mold making, and logo making. In the process of machinery manufacturing, low-stress steel font codes can be used to mark information about various equipment, parts, and products, such as name, model, specification, etc.

Contact Now

Low stress figure OEM refers to an original equipment manufacturer that specializes in creating precise and clear imprints on metal surfaces using low-impact marking methods. Their machinery, processes, and techniques are designed to minimize the amount of force and pressure applied to the metal surface, reducing the risk of damage or deformation.Low stress figure OEMs typically use specialized equipment such as dot peen marking machines, laser engraving systems, or electrochemical etching machines to create high-quality marks on metal surfaces.

Contact Now

Low-stress steel marking is a technique used to imprint text or designs onto metal surfaces, such as pipes, tanks, and equipment, without causing damage to the material. This is achieved by using a low-impact marking method that reduces stress on the metal, preventing cracking or deformation.There are several techniques used for low-stress steel marking, including dot peen marking, laser engraving, and electrochemical etching. Dot peen marking is a process where a series of small dots are stamped onto the metal surface in a specific pattern to create the desired text or design.

Contact Now

A low-stress letter is a type of letter marking method used to create clear and legible imprints on metal surfaces without causing damage or stress to the material. This technique involves using a low-impact marking method that reduces the amount of force and pressure applied to the metal surface, preventing cracking, deformation, or other types of damage.There are several low-stress letter marking techniques available, including dot peen marking, laser engraving, and electrochemical etching.

Contact Now

Low stress steel fonts are designed for use with metal stamping and marking applications where there is a risk of stress or deformation in the material being stamped.

Contact Now

A handheld low-stress steel word stamp is a type of stamp that is used to imprint words or text onto various materials, typically made from steel. These stamps are designed to be held by hand and applied with moderate pressure, using a hammer or mallet to create the impression.Here are some details and considerations for this type of product:Material: The steel used in these stamps is typically hardened to resist wear and tear, ensuring longevity and consistent performance.Size and Font: Handheld low-stress steel word stamps come in various sizes and font styles.

Contact Now

Custom low-stress stamps are tools used for marking various surfaces with a particular design or text. These stamps are designed to minimize the amount of pressure required to create an impression, making them ideal for repetitive stamping tasks that can cause hand fatigue.These stamps are typically made from polymer materials such as rubber, silicone or photopolymer. The design is etched onto the stamp with a laser or photoengraving process.

Contact Now

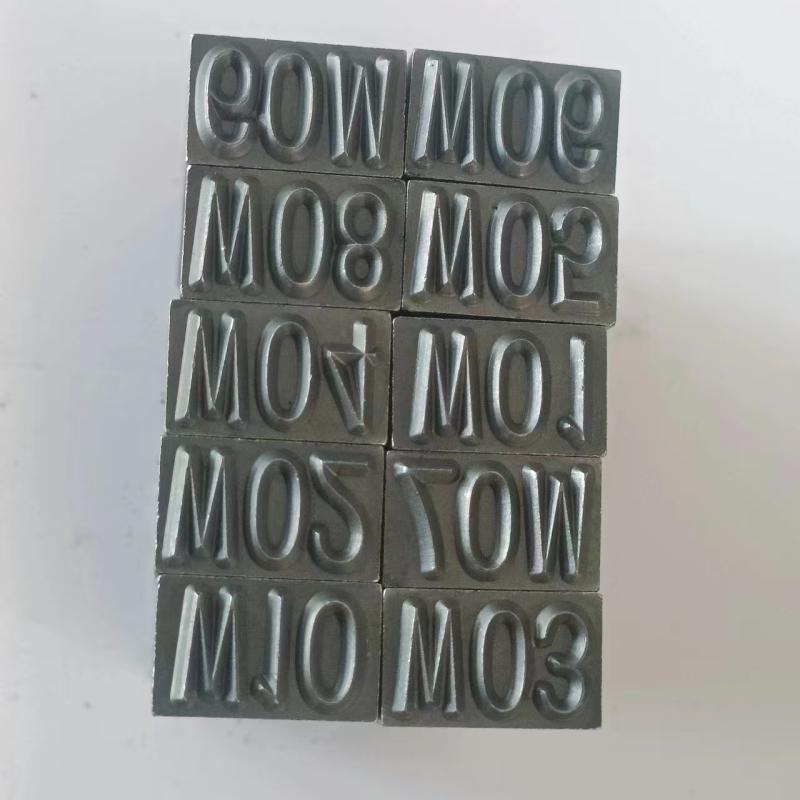

Low Stress Round-Face Number Stamp Sets is a stamp made using high-end precision die steel, which is usually used in fields such as aerospace, nuclear industry and oil industry. This type of stamp uses advanced production processes and materials to ensure a high degree of precision, durability and reliability.Precision die steel is a steel with high hardness, excellent corrosion resistance, high temperature stability and precision machining capability.

Contact Now

Bent stamp products are typically metal components that have been formed through a bending process. The bending process involves using a press brake, roll bender or other industrial equipment to manipulate the shape of the metal blank so that it conforms to a specific angle or radius.The precise specifications of bent stamp products can vary widely depending on the specific application and industry in which they are used.

Contact Now

Welder stamps are used to perceive welded components and can consist of facts like the welder's identification number, date of welding, fabric specifications, or inspector approval. Here are some frequent small print and issues for welder stamps:Stamp Size: Welder stamps come in more than a few sizes. The measurement you select will rely on the precise sketch or sample you favor to imprint onto your welded parts.Design Options: Welder stamps can be custom-made with a vast vary of designs, such as letters, numbers, symbols, and patterns.

Contact Now

The Custom Handheld Steel Stamp is a durable, affordable, easy-to-carry, and well-printed stamp that is suitable for many occasions. It provides users with more unique and practical seal options, which can meet the individual needs of users, and allow users to enjoy a more convenient, efficient and beautiful use experience.Custom hand held metallic stamps are personalized stamps that may be custom designed in step with purchaser desires, typically including a take care of and a stamp head which can update letters, numbers and photos.

Contact Now

The company has more than 30 sets of vertical machining center, carving and milling machine, CNC lathe, grinder, wire cutting, electric spark, punch machine, heat treatment, sand blasting and other CNC equipment.In order to meet the different requirements of different customers, product support customized, according to customer requirements to process customized, we provide a series of comprehensive steel word stamping, steel seal engraving at the industry-leading price. Provide different grades of letter marking, alphabet stamping, steel engraving products.

Contact Now

A steel font is a standard font code that can be used to quickly print Chinese characters, and it is composed of a series of steel font molds. To make a steel font, you need to prepare some fonts, which can be obtained from an existing font library or made by hand. The process of making steel codes can be roughly divided into the following steps:1. Prepare the font mold: choose the appropriate font size and number according to the number of Chinese characters to be printed, and arrange the font pattern according to a certain rule.2.

Contact Now

The advantages of steel typesetting machines include:1 High efficiency: Steel typesetting machines can quickly and accurately create high-quality marks on various materials, improving production efficiency and reducing labor costs.2 Versatility: Steel typesetting machines can create a wide range of marks, including letters, numbers, logos, and symbols, making them suitable for various industrial applications.3 Durability: Steel typesetting machines are made of high-quality materials that are durable and resistant to wear and tear, ensuring long-term use and reliability.4 Customizability: Steel

Contact Now

Composite steel fonts, also known as stainless steel composite letters, are a type of signage that is widely used in a variety of applications such as commercial buildings, shopping malls, and public spaces. These fonts are constructed using a combination of materials such as high-quality stainless steel, acrylic, and other materials to create a durable and visually appealing sign.The process of creating composite steel fonts involves cutting the letters from high-quality stainless steel sheets using precision tools such as lasers or water jets.

Contact Now

A customized steel prefix refers to a unique or personalized identifying code or symbol that is added to steel components or products. This prefix is often used for purposes such as part numbering, product identification, or traceability. Here are some key points about customized steel prefixes:Purpose: Customized steel prefixes are used to uniquely identify steel components or products.

Contact Now

Stamped steel parts are commonly used in various industries, including automotive, appliances, construction, and more. They are created through a process called metal stamping, where flat sheets of steel are shaped and formed using a press and stamping dies.

Contact Now

Steel initial stamps are used to imprint letters, numbers or symbols on a variety of materials, usually made of steel.

Contact Now

A steel frame is a support device used in buildings and other structures, usually made of steel. They can be installed in multiple locations such as roofs, walls, floors, etc. to provide support and stability.Custom steel form brackets are designed and fabricated according to specific project requirements.

Contact Now

What is the material of the steel prefix, it is a medium carbon steel with high strength, which is generally used in a normalized state, and when the mechanical properties are high, the quenching and tempering treatment is adopted. The cold deformation plasticity is medium, and the machinability of annealing and normalizing is better than that of quenching and tempering.

Contact Now

Metal stamps are used to imprint designs or patterns onto a range of metals such as steel, brass, and aluminum. They are generally made from amazing hardened device metal and come in a range of shapes and sizes, relying on the unique application.Here are some frequent important points and issues for metallic stamps:Stamp Size: Metal stamps come in a range of sizes - small, medium, and large.

Contact Now

Machine-typed steel code refers to a type of identification or marking system used in the steel industry to label and track steel products. The code is typically stamped or etched onto a metal plate or tag, which is then attached to the steel product.Machine-typed steel codes may include a wide range of information, including lot numbers, production dates, material specifications, and other identifying markers.

Contact Now

A custom steel grade is a steel that is designed and produced according to a customer's specific needs and requirements. Usually, these requirements include requirements for the use of materials, environment, strength, hardness, etc. Compared with standard steel, customized steel has more precise property matching, higher quality controllability and higher production efficiency.In the production process of customized steel grades, it is first necessary to understand the needs of customers, including steel usage, specifications, production batch quantities, delivery time, etc.

Contact Now