A rolling die is a tool used in metal processing, which usually consists of two or more rollers, which can plastically deform metal sheets, pipes, etc. Roll die processing technology is widely used in various industries, such as automotive, aviation, construction and other fields.The working principle of the rolling mold is to plastically deform the metal material through the roller, so that it can change its shape and size. During rolling die processing, the metal material is conveyed between the rollers, and is continuously pressed and stretched by the rollers.

Contact Now

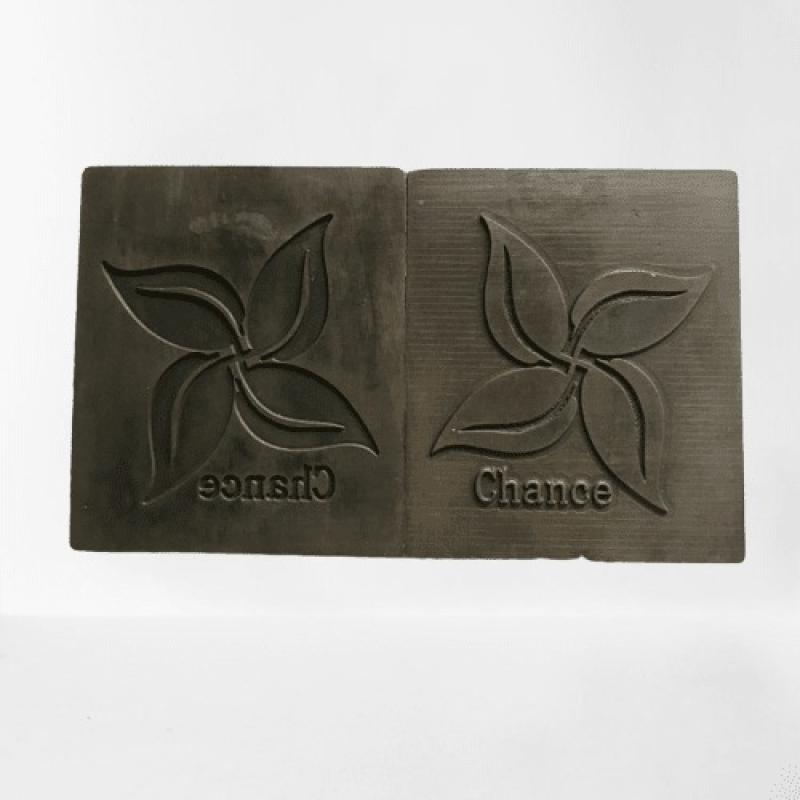

Custom leather roll dies are tools used in the production of leather goods, such as belts, wallets, and bags. These dies are typically made of metal and are used to create embossed or engraved patterns on leather.To create a custom leather roll die, you will need to provide the design or pattern that you want to appear on the die. This can be done either by providing a digital file or by sketching out your design on paper.Once you have your design ready, you can work with a manufacturer or supplier who specializes in creating custom dies.

Contact Now

Stamped steel parts are commonly used in various industries, including automotive, appliances, construction, and more. They are created through a process called metal stamping, where flat sheets of steel are shaped and formed using a press and stamping dies.

Contact Now

Whether your product is metal, wood, leather, embellishes or plastic etc., we have an skilled crew geared up to produce your customized sheet metal stamps with precision and detail. When you desire to repeat an picture or layout alongside leather-based strips such as belts, we will produce excessive first-rate brass or metal roll molds to your specs to go well with your roll marking desktop or for guide use. There's nothing extra incredible than a appropriate LOGO stencil.

Contact Now

Bent stamp products are typically metal components that have been formed through a bending process. The bending process involves using a press brake, roll bender or other industrial equipment to manipulate the shape of the metal blank so that it conforms to a specific angle or radius.The precise specifications of bent stamp products can vary widely depending on the specific application and industry in which they are used.

Contact Now

A machine fixture is a specialized tool used to securely hold a workpiece in place during machining operations.

Contact Now

A hand tapping fixture is a tool that is used to securely hold a tap and guide it during manual tapping operations. This type of fixture is commonly used in metalworking applications where precise threading is required.Hand tapping fixtures typically consist of a base that attaches to the workpiece or workbench, and a guide block that holds the tap in place at a precise angle.

Contact Now

Machine-printed steel code refers to a method of marking or engraving codes, such as alphanumeric characters or barcodes, onto steel surfaces using a machine or automated printing system. This process is commonly used in industries such as manufacturing, logistics, and inventory management, where it is necessary to label steel components or products for identification, tracking, or quality control purposes.The machine-printed steel code can be created using various techniques such as laser engraving, inkjet printing, or dot peening.

Contact Now

Mechanical letters are a type of keyboard key that relies on mechanical switches to register keystrokes. Unlike electronic keys, which rely on a rubber dome or membrane to create an electrical connection, mechanical keys use individual switches for each key.Mechanical keys can be customized to different levels of sensitivity and provide a tactile feedback when pressed, allowing typists to feel the key being actuated.

Contact Now

Hand-held stamp earrings is the perfect way to mark a range of rings that can be struck with a mallet, and the patterns on the stamps are custom-made to your requirements. A clear and lasting affect of a metallic stamp suggests a distinct character.Jewelry stamp merchandise are specialised equipment used to imprint designs, trademarks or textual content onto metallic surfaces of rings components.

Contact Now

A mechanical digital combination lock is a mechanical lock that uses a digital password to open. It usually consists of a dial wheel that rotates automatically, a set of dial codes, and a mechanical device that controls the lock body. The user needs to turn the dial on the dial to the correct position in the correct order in order to open the lock.Compared with traditional key locks and electronic combination locks, mechanical digital combination locks have several advantages.

Contact Now

Metal stamps are used to imprint designs or patterns onto a range of metals such as steel, brass, and aluminum. They are generally made from amazing hardened device metal and come in a range of shapes and sizes, relying on the unique application.Here are some frequent important points and issues for metallic stamps:Stamp Size: Metal stamps come in a range of sizes - small, medium, and large.

Contact Now

The Custom Handheld Steel Stamp is a durable, affordable, easy-to-carry, and well-printed stamp that is suitable for many occasions. It provides users with more unique and practical seal options, which can meet the individual needs of users, and allow users to enjoy a more convenient, efficient and beautiful use experience.Custom hand held metallic stamps are personalized stamps that may be custom designed in step with purchaser desires, typically including a take care of and a stamp head which can update letters, numbers and photos.

Contact Now

These are just a few examples of the types of product details that may be relevant for curved stamps. Ultimately, the specific requirements will depend on the needs of the customer and the intended use of the stamp. A reputable metal stamp manufacturer will work closely with their customers to understand their needs and provide high-quality custom stamped products that meet those needs.The specific details of a curved stamp can vary depending on the application and the materials being stamped.

Contact Now

Jewelry design stamps is a professional manufacturer of steel stamps. Our company Jewelry, as one of the products of people's pursuit of beauty, has been concerned and sought after. And jewelry design stamp, is used to mark jewelry on an important tool.Jewelry design stamps can be traced back to the early history of stamp design, which was originally designed to mark jewelry items with information such as material, weight, grade, finish, etc.

Contact Now

A letter stamp punch set is a device used to imprint character letters onto a range of materials, such as metal, leather, and wood. The set normally consists of a choice of steel stamps that have the letters of the alphabet engraved on their faces, as nicely as numbers and some punctuation marks.The stamps can be made from a number materials, such as metal or brass, and can also have a hardened floor to make certain durability.

Contact Now

A scroll wheel is a small, cylindrical component located between the left and right buttons on a computer mouse. It allows users to scroll through content on their screen without having to drag the page up or down manually. When the user rolls the wheel forward or backward, it sends signals to the computer, which in turn scrolls the content up or down.Scroll wheels were first introduced by Microsoft in 1996 as part of their IntelliMouse line of computer mice.

Contact Now

Convex and concave mold is a special mold, mainly used to produce convex and concave shape parts, such as abrasives, plastic products, metal parts, etc., is a commonly used mold in many industries. Its function is to produce high-precision parts or products due to the need to accurately match two molds when producing products with the same convex and concave shape. The production process of convex and concave molds is generally divided into the following steps: 1.Design the shape, size and fitting principle of the two modules of convex and concave.

Contact Now

Steel particles, copper particles, conjoined particles, special particles, our factory has advanced production lines and a group of experienced technicians, the products are mainly used in aluminum-plastic packaging machine, granule packaging machine, food packaging machine, liquid packaging machine, water injection printing machine, sealing machine, metal hose sealing machine, ink wheel coding machine, automatic coding machine, Manual coding machine and carton batch number, production date, expiration date printing, the factory has a set of strict control of the shap

Contact Now

Number Punches is a tool commonly used for printing and marking, usually made of high-quality steel. They can be used to print text, numbers or identification symbols on a variety of materials.A high-end precision mold is a tool used to manufacture precision parts. They are usually made of high-strength alloy steel or other special materials and are precision machined.

Contact Now

When a raised image is required, Embossing is the most effective marking method. To obtain an embossed (raised) image on thin sheets of material such as aluminum, brass, copper, stainless steel, tin, etc. the Embossing Die Set needs to be used in a press.An Embossing Die Set is comprised of two Metal Stamp parts, male and female.

Contact Now

Machine-typed steel code refers to a type of identification or marking system used in the steel industry to label and track steel products. The code is typically stamped or etched onto a metal plate or tag, which is then attached to the steel product.Machine-typed steel codes may include a wide range of information, including lot numbers, production dates, material specifications, and other identifying markers.

Contact Now

The low-stress steel code is a special type of steel code, the main feature of which is the ability to maintain a low stress level during use. This makes low-stress steel codes excellent in a wide range of applications, especially where high strength, low stress and durability are required.Low-stress steel fonts are also widely used in machinery manufacturing, mold making, and logo making. In the process of machinery manufacturing, low-stress steel font codes can be used to mark information about various equipment, parts, and products, such as name, model, specification, etc.

Contact Now

A customized steel prefix refers to a unique or personalized identifying code or symbol that is added to steel components or products. This prefix is often used for purposes such as part numbering, product identification, or traceability. Here are some key points about customized steel prefixes:Purpose: Customized steel prefixes are used to uniquely identify steel components or products.

Contact Now