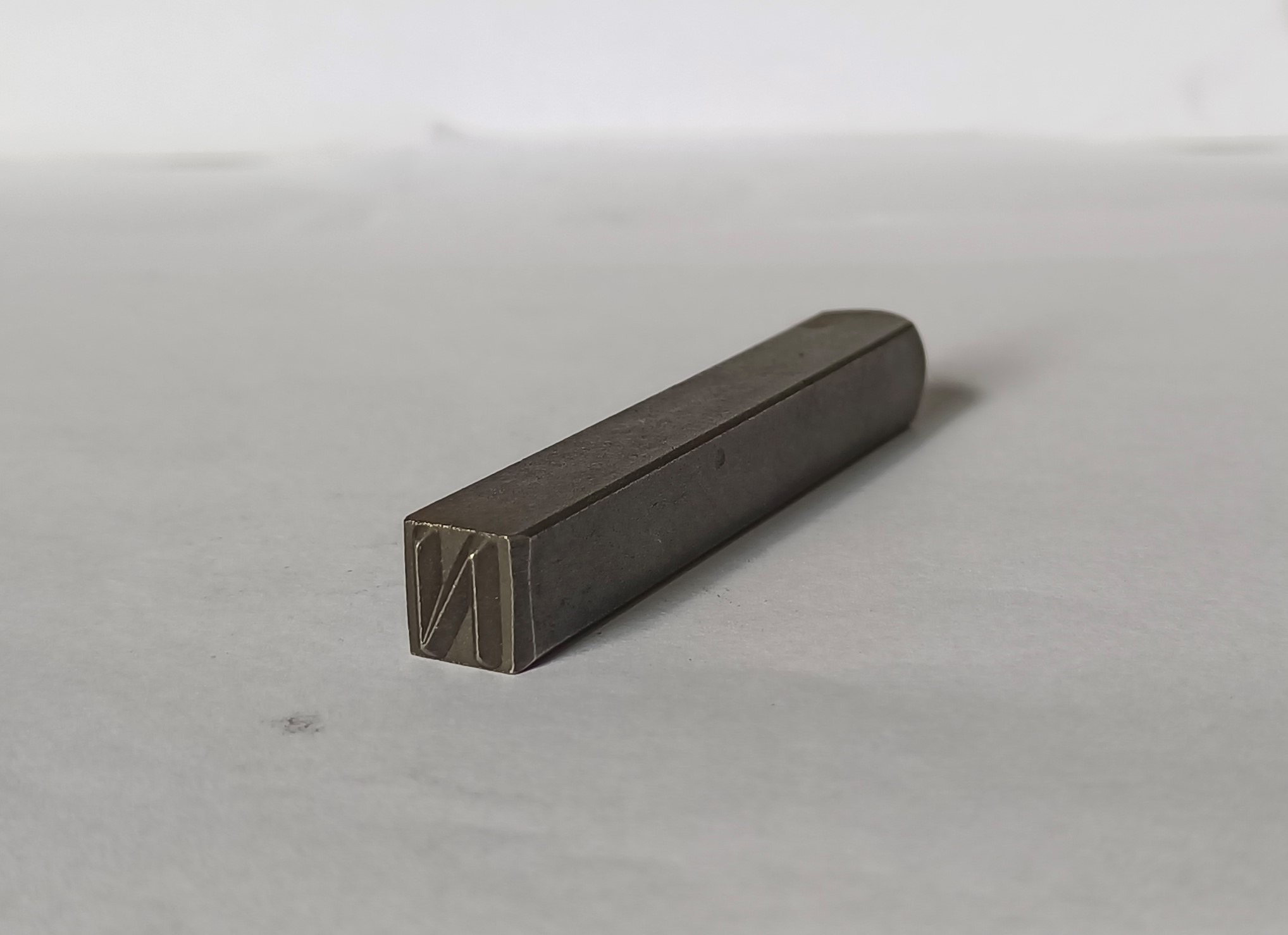

Metal Stamp

As a metal stamp manufacturer, your company is likely involved in the production of stamped metal components for a wide range of industries and applications. Metal stamping is a process that involves feeding a flat sheet of metal into a stamping press, which then uses a die to cut and shape the metal into the desired component.

Metal stamping can be used to create a wide variety of products, from simple washers and brackets to more complex parts with intricate designs and geometries. Some common materials used in metal stamping include steel, aluminum, copper, brass, and various alloys.

As a metal stamp manufacturer, your company may offer a range of services beyond just stamping, such as design and engineering support, finishing and coating options, and secondary operations like bending, welding, and assembly.

Overall, metal stamping is a versatile and cost-effective manufacturing method that can meet the needs of a wide range of industries and applications. A reputable and experienced metal stamp manufacturer can provide high-quality stamped components that meet the rigorous demands of modern manufacturing.

These are just a few examples of the types of details that might be important for a metal stamping product. Ultimately, the specific requirements will depend on the needs of the customer and the intended application of the component. A reputable metal stamp manufacturer will work closely with their customers to understand their requirements and provide high-quality stamped components that meet those needs.

The details of a metal stamp product can vary widely depending on the specific application and requirements. However, some common details that may be relevant for many metal stamping products include:

Material: The type and grade of metal used for the stamped component.

Dimensions: The size and shape of the component, including thickness, width, length, and any critical tolerances.

Surface finish: The finish or coating applied to the surface of the component, such as plating, anodizing, painting, or powder coating.

Features: Any unique features or design elements required for the component, such as holes, slots, bends, or embossing.

Quantity: The desired production quantity of the component, which can affect the manufacturing process and cost.

Delivery requirements: Any special delivery or packaging requirements for the component, such as just-in-time delivery or specialized packaging for sensitive components.