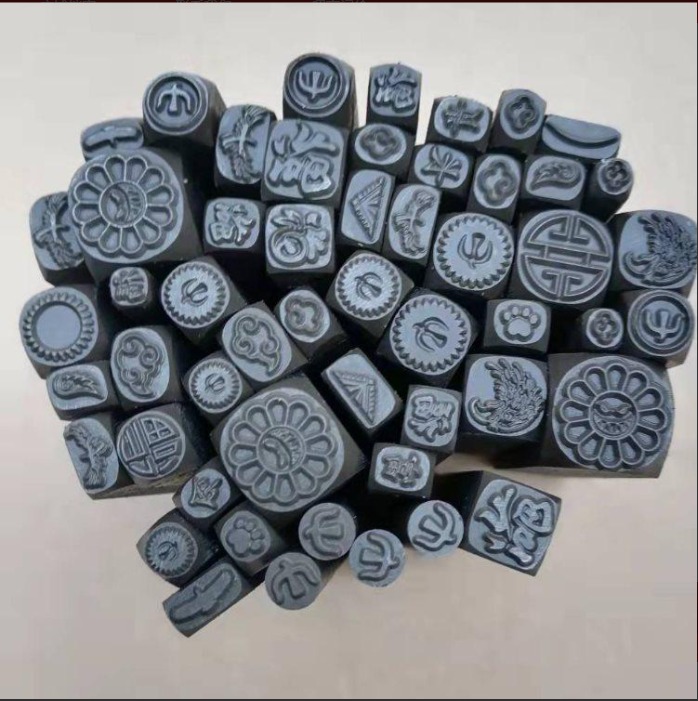

Custom Steel Hand Stamp Of Metal

A custom steel hand stamp of metal is a tool used to imprint designs, logos or text onto metal surfaces such as plates, tags, keys, and other items. These stamps are typically made from high-quality steel and feature raised letters, symbols or designs that create an indentation when struck with a hammer or mallet.

Custom steel hand stamps can be customized to fit the specific design and functionality requirements of each customer. This may include creating a custom font or logo, or choosing from a selection of existing designs. Once the design is finalized, the manufacturer will create a steel stamping die that can be used to create the stamp impressions.

When using a custom steel hand stamp of metal, it's important to use even pressure and strike the stamp squarely to ensure that the impression comes out clear and legible. The stamp is typically placed onto the metal surface and struck with a hammer or mallet to create the indentation.

Custom steel hand stamps of metal are popular among artisans, designers, and crafters who want to add a personalized touch to their metal products. They can also be useful for branding and marketing purposes, allowing businesses to imprint their logos or names onto products for increased brand recognition. With proper care and maintenance, a custom steel hand stamp can provide years of reliable use.

For marking steel and other metals, the most practical and economical option is marking with Steel Stamps. Custom Metal Hand Stamps from ISI deliver quality marks with a design made to your specifications.

While other marking methods can be more costly and possibly involve lasers or hazardous chemicals, choosing to use a Steel Hand Stamp is the most cost-effective and the easiest “do it yourself” permanent marking solution. All you need is a hammer and away you mark.

When using a custom steel hand stamp of metal, it's important to use even pressure and strike the stamp squarely to ensure that the impression comes out clear and legible. The stamp is typically placed onto the metal surface and struck with a hammer or mallet to create the indentation.