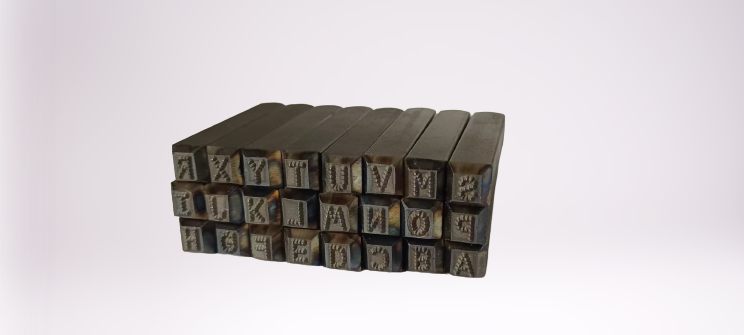

Curved Steel Seal

Curved stamping products offer several advantages over flat stamping products:

Aesthetically pleasing: Curved stamping products can provide a more visually appealing appearance compared to flat products. They can add a unique design element, and the curves can create a sense of flow that enhances the overall look of the product.

Enhanced structural strength: Curved shapes can provide enhanced structural strength compared to flat shapes. The curvature distributes stress and weight evenly, which can increase the product’s load-bearing capacity.

Versatility: Curved stamping products are incredibly versatile and can be used in a wide range of applications. They can be used in the automotive industry, aerospace, construction, and many other industries.

Reduced material waste: When producing curved stamping products, less material is wasted compared to flat stamping products. The curves can be designed to follow the natural shape of the material, requiring less cutting and reducing material waste.

Improved functionality: Curved stamping products can have improved functionality over flat products. They can provide better aerodynamics, reduce wind resistance or provide a better fit between components with different shapes.

Overall, curved stamping products offer numerous advantages over flat stamping products, including aesthetic appeal, enhanced structural strength, versatility, reduced material waste, and improved functionality.

Bent stamp products are typically metal components that have been formed through a bending process. The bending process involves using a press brake, roll bender or other industrial equipment to manipulate the shape of the metal blank so that it conforms to a specific angle or radius.

The precise specifications of bent stamp products can vary widely depending on the specific application and industry in which they are used. For example, bent stamp products may be used as brackets, supports, or connectors in construction, automotive manufacturing, or aerospace industries.

Some common types of bent stamp products include:

Angle brackets: These are L-shaped metal brackets that are commonly used to provide support or to connect two components in different planes.

U-shaped channels: These are bent stamp products that form a U-shape channel and can be used for framing, supports or guides.

Tubing: Tubing is often produced by bending flat strips of metal into a cylindrical shape.

Curved brackets: These are bent stamp products that are formed to fit precisely around a curved surface or object.

Overall, bent stamp products play an essential role in many industries and applications, providing strength and support in structures and machinery. The wide range of shapes and angles that can be produced make them a versatile option for manufacturers looking to create custom metal components with specific dimensions and properties.