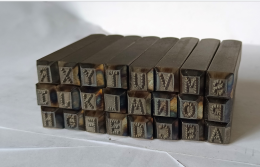

Low Stress Letter

We are a manufacturer of metal stamps with over 30 years of experience and we can make dot, graphic, number, letter or round stamps to your specifications. Whether you need a logo, an acronym, or a special pattern, word or phrase. Our team is experienced, reasonable price according to the drawings customized production.

Metal, wood, leather or plastic used for steel stamp No matter what your product is, we have an experienced team ready to produce your custom low stamp precision and super detail stamps.

A low-stress letter is a type of letter marking method used to create clear and legible imprints on metal surfaces without causing damage or stress to the material. This technique involves using a low-impact marking method that reduces the amount of force and pressure applied to the metal surface, preventing cracking, deformation, or other types of damage.

There are several low-stress letter marking techniques available, including dot peen marking, laser engraving, and electrochemical etching. Dot peen marking uses a series of small dots stamped onto the metal surface in a specific pattern to create the desired letters. Laser engraving uses a high-powered laser to remove material from the metal surface, creating a permanent mark. Electrochemical etching involves applying an electric current to the metal surface through a stencil or mask, creating a chemical reaction that imprints the text or design onto the metal.

The advantages of using a low-stress letter marking method include:

Reduced risk of damage to the metal: Low-stress letter marking techniques reduce the amount of force and impact on the metal surface, which helps to prevent cracking, deformation, or other types of damage that can compromise the integrity of the material.

Enhanced readability: Because low-stress letter marking methods create a clear and legible mark on the metal surface, it is easy to identify components and parts, which can save time during inspection and maintenance processes.

Improved traceability: By using low-stress letter marking techniques to imprint unique identification numbers, part numbers, or other important information onto metal surfaces, manufacturers can improve traceability throughout the product lifecycle.

Compliance with industry standards: Many industries have strict regulations and guidelines regarding the marking and identification of metal components and parts. By using low-stress letter marking techniques, manufacturers can ensure that their products meet these standards and comply with industry regulations.