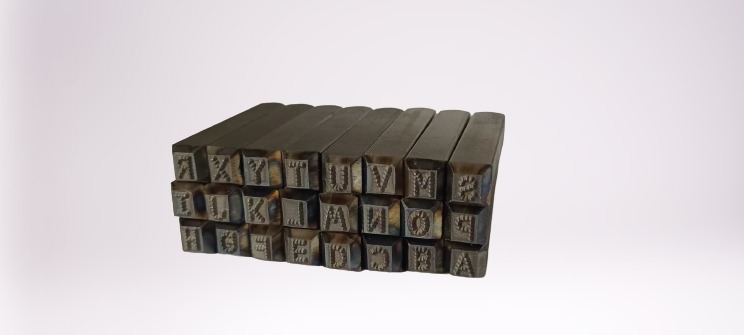

Low Stress Round-Face Number Stamp Sets

Low Stress Round-Face Number Stamp Setsused to make seals has the following advantages:

High hardness: The hardness of Low Stress Round-Face Number Stamp Setsis very high, which makes it able to maintain stability and wear resistance for a long time during use. This makes it particularly suitable for making seals, which need to be used frequently and must maintain a clearly visible pattern.

Excellent Corrosion resistance: Low Stress Round-Face Number Stamp Setshas excellent corrosion resistance, which makes it resistant to environmental chemicals and other corrosive factors. Since some seals may be used in harsh environments, this corrosion resistance is important to ensure the long-term reliability of the seal.

High temperature stability: Low Stress Round-Face Number Stamp Setscan maintain its structural strength and mechanical properties under high temperature environment. This makes it ideal for making seals in areas such as the nuclear industry, aerospace and petroleum industries, where high-temperature environments are often involved.

Precision Machining capability: Low Stress Round-Face Number Stamp Setshas excellent precision machining capability, which allows it to be made into highly accurate parts and molds. This precision is important because seals require extremely high precision to ensure that they can be properly engraved and identified.

High strength: Low Stress Round-Face Number Stamp Setshas very high strength, which allows it to withstand a variety of pressures and stresses, thus improving the service life and durability of the seal.

To sum up, Low Stress Round-Face Number Stamp Setsis the ideal material for making seals, because it has many advantages such as high hardness, excellent corrosion resistance, high temperature stability, precision machining ability and high strength.

Low Stress Round-Face Number Stamp Sets is a stamp made using high-end precision die steel, which is usually used in fields such as aerospace, nuclear industry and oil industry. This type of stamp uses advanced production processes and materials to ensure a high degree of precision, durability and reliability.

Precision die steel is a steel with high hardness, excellent corrosion resistance, high temperature stability and precision machining capability. It can maintain its structural strength and mechanical properties in high temperature environments, while having excellent corrosion resistance and wear resistance. This makes precision tool steel ideal for stamps, which are used frequently and must maintain a clearly visible pattern.

When manufacturing precision mold steel stamps, advanced processing technologies such as CNC cutting, CNC machining, spark discharge machining, and wire cutting machining are usually used to ensure that the stamps have highly accurate dimensions and shapes. Then, the stamp is subjected to surface treatment, such as polishing, anti-rust treatment, etc., to improve its appearance and durability.

In conclusion, the Low Stress Round-Face Number Stamp Sets has high precision, durability and reliability, and is an ideal stamp material, especially suitable for fields requiring high precision, high strength and high durability.

To better assist you in choosing a font size, we have put together a PDF comparison chart. Simply print out the file on letter size paper, making sure it is set to print at actual size.