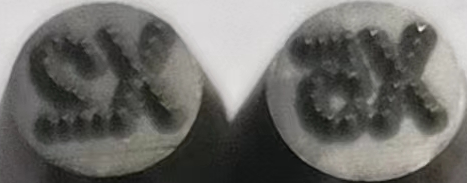

Punctate Steel Mark

The advantages of a punctate steel mark include:

Durability: Because punctate steel marks are created by imprinting the metal surface itself, they are highly resistant to wear and fading over time.

Legibility: PSMs create a clear and precise mark that is easy to read and identify, even in harsh environments or when viewed from a distance.

Compliance: Punctate steel marks are widely recognized and accepted as a standard marking method in many industries, meaning that they can help manufacturers meet industry regulations and standards.

Overall, punctate steel marking is a reliable and effective way to create permanent marks on metal surfaces, providing durability, legibility, and compliance with industry standards.

A punctate steel mark (PSM) is a type of marking method used to create a clear and permanent indent or impression on metal surfaces. This technique involves using a series of closely spaced dots or small impressions, rather than continuous lines, to form the desired text or design.

Punctate steel marking is often used in industries such as aerospace, automotive, and military, where manufacturers need to create durable and legible marks on metal components and parts. The technique is typically performed using specialized equipment, such as a dot peen marking machine, which uses a series of pins to stamp the metal surface with the desired pattern of dots.