Steel Lettering For Auto Parts

Auto parts steel lettering and the quenching process provide numerous advantages in terms of durability, visibility, customization, improved mechanical properties, and cost-effectiveness. These benefits make them a popular choice for manufacturers looking to produce high-quality and long-lasting auto components.

Auto parts steel lettering and quenching process product is a specialized type of auto part that undergoes a unique manufacturing process to achieve specific attributes. Here is an introduction to this product:

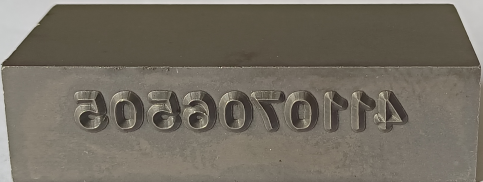

Steel lettering: Auto parts steel lettering refers to the technique of adding lettering or text onto auto parts made of steel. This process involves various methods like laser engraving, mechanical engraving, or using stickers or decals. Steel lettering provides a way to mark or identify different components, manufacturer logos, part numbers, or any other necessary information on the auto parts.

Quenching process: Quenching is a heat treatment process applied to steel auto parts to enhance their hardness and strength. During quenching, the heated steel component is rapidly cooled in a controlled manner. This rapid cooling helps in achieving a desirable hardness while maintaining the desired mechanical properties of the part.

Benefits: Auto parts with steel lettering and quenching process offer several advantages. The steel lettering allows for easy identification and traceability of auto parts, helping with accurate assembly, maintenance, and repairs. The quenching process improves the mechanical properties of the auto parts, making them stronger, more durable, and resistant to wear and tear. This often results in improved performance, reliability, and longevity of the auto parts.

Common applications: Auto parts steel lettering and quenching process are commonly applied to various components in the automotive industry. This includes engine parts, suspension components, transmission parts, brake system components, and others. Steel lettering assists in part identification, while the quenching process ensures that these parts can withstand the demanding conditions of their specific applications.

Customization and quality control: Manufacturers of auto parts with steel lettering and quenching process often provide customization options to meet specific customer requirements. This allows for tailored designs, logos, or text to be incorporated into the steel lettering. Additionally, these manufacturers follow strict quality control procedures to ensure that the steel lettering is precise, durable, and legible, while the quenching process meets industry standards and customer specifications.

It's important to note that the specific details, methods, and processes involved in auto parts steel lettering and quenching can vary depending on the manufacturer, type of auto part, and customer requirements.