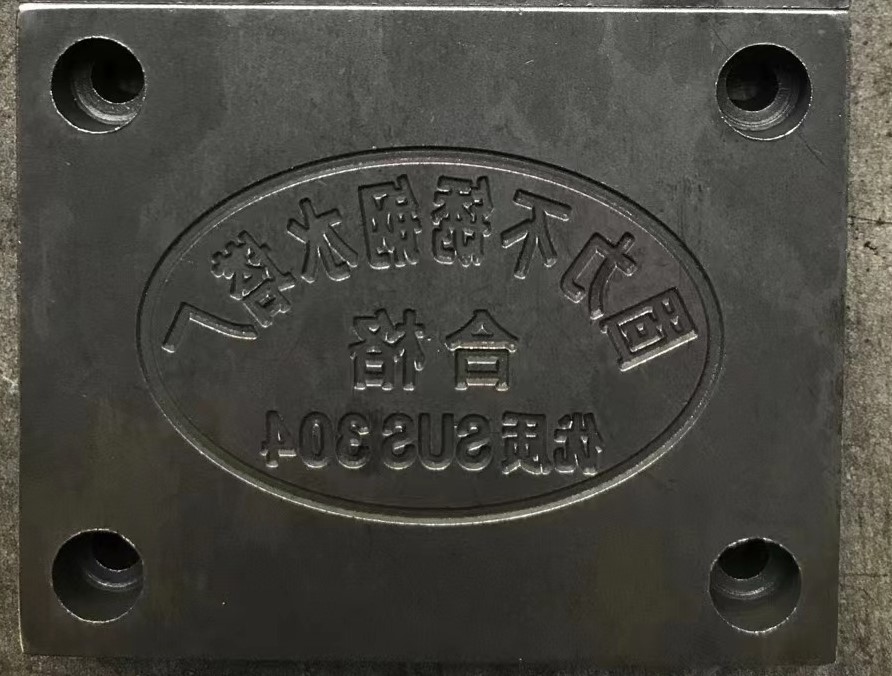

Embossing Die Sets

Embossing die sets are specialized tooling used to create raised or depressed designs on a wide range of materials such as paper, plastic, and metal. The die set typically consists of two parts: a male punch and a female die.

When the material is placed between the punch and die, pressure is applied to create the desired design or pattern. The male punch contains the reverse image of the design, while the female die contains the positive image.

Embossing die sets can be used in a variety of applications such as packaging, printing, and crafting. They may also be used in conjunction with other types of equipment such as hot stamping machines or letterpress equipment.

When selecting embossing die sets, it is important to consider factors such as durability, accuracy, and compatibility with existing equipment and processes. A quality die set will be made from high-quality materials such as hardened steel, and will provide accurate and consistent results over time.

Overall, embossing die sets can be a valuable tool for businesses and individuals looking to add texture and dimension to their products or designs. Working with an experienced tooling supplier can help ensure that the final product meets the needs and specifications of the customer.

Embossing module is a specialized equipment used to create raised or depressed designs on various materials such as paper, plastic, or metal. It is usually composed of a punch and die set that produces the design on the material.

Embossing modules can be used for a variety of applications including packaging, printing, and crafting. They are compatible with different types of equipment such as hot stamping machines or letterpress equipment. They come in different shapes and sizes depending on the intended use.

Some of the product details of an embossing module may include:

Material: Embossing modules are usually made from high-quality materials such as hardened steel to ensure durability and long-lasting use.

Design: The design of the embossing module should be precise and detailed, whether it is a custom design or a standard design. The module's design should be able to create the desired effect on the intended material.

Compatibility: The embossing module should be compatible with different types of equipment and processes. This allows for seamless integration into existing manufacturing systems.

Customization: The embossing module can be customized to suit the specific needs and requirements of the customer. This includes customization of the design, shape, and size to match the intended application.

Application: The embossing module can be used for various applications such as foil stamping, debossing, or blind embossing. Each application requires a unique design and specific product details.

Overall, an embossing module is a valuable tool for businesses and individuals looking to add texture and dimension to their products or designs. Working with an experienced tooling supplier can help ensure that the final product meets the needs and specifications of the customer.