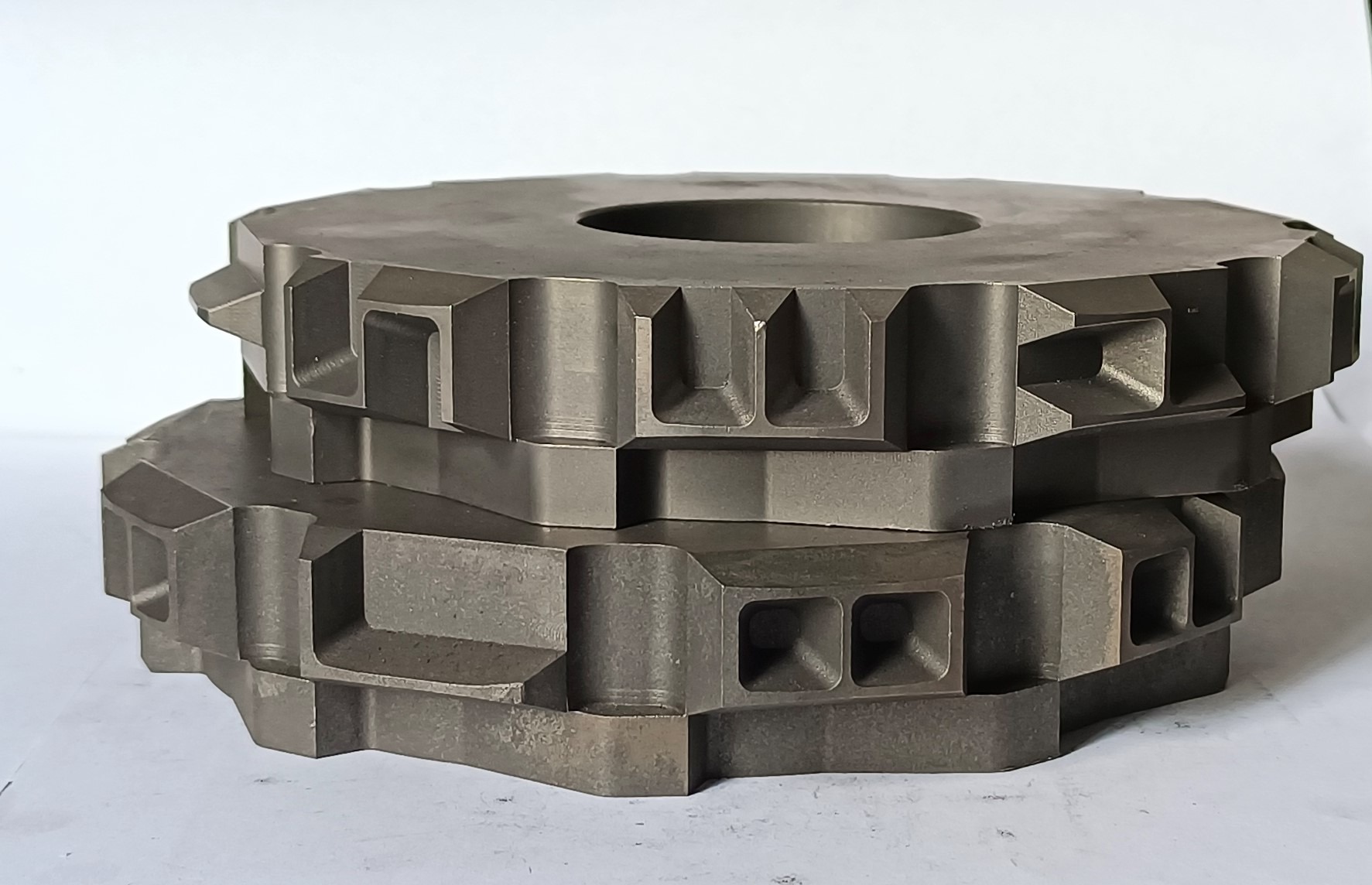

Embossing Module

An embossing module is a component of a machine that is used to create raised or indented patterns on various materials such as paper, cardboard, plastic, and metal. This module can be integrated into a variety of machines including label printing machines, business card printers, and roll-fed printing equipment.

Embosing modules typically consist of an embossing plate, a counterforce roller, and a pressure mechanism that applies force to the plate to create the embossed pattern on the material passing through it. The embossing plate is typically made from a durable metal such as steel, and features the desired pattern or design.

The counterforce roller is positioned opposite the embossing plate and works in conjunction with it to apply pressure to the material being embossed. The pressure mechanism applies pressure to the embossing plate, which in turn presses the material against the counterforce roller to create the embossed pattern.

Overall, an embossing module is a critical component of any machine that requires embossing capabilities, such as printing or packaging equipment. A high-quality embossing module can provide precise and consistent results, making it a valuable tool for many industries and applications.

When a raised image is required, Embossing is the most effective marking method. To obtain an embossed (raised) image on thin sheets of material such as aluminum, brass, copper, stainless steel, tin, etc. the Embossing Die Set needs to be used in a press.

An Embossing Die Set is comprised of two Metal Stamp parts, male and female. The male part is produced with a face that features the raised image, while the female part is produced with a sunk-engraved image.

To produce the two parts of an Embossing Die Set with the right clearance, it is imperative that the customer specifies the exact thickness of the material to be embossed.