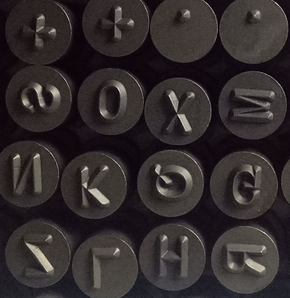

Machine Typed Steel Code

Machine-made steel code products offer several advantages over other identification or marking methods. Some of these advantages include:

Consistency and accuracy: Machine-made steel code products are created using precision equipment, ensuring that each code is consistent and accurate. This can help reduce errors and improve efficiency in tracking and identifying steel products.

Durability: Steel code products are made from durable materials that can withstand harsh environments, extreme temperatures, and heavy use. This helps to ensure that the identification code remains legible and intact throughout the lifespan of the steel product.

Compatibility: Machine-made steel codes can be easily integrated with existing manufacturing processes and equipment, allowing for seamless tracking and identification of steel products throughout the supply chain.

Traceability: Steel code products allow for easy traceability of steel products from production to shipping and beyond. This can help improve quality control, identify potential issues or defects, and ensure that steel products meet necessary standards and regulations.

Customization: Steel code products can be customized to include specific information such as lot numbers, production dates, and material specifications. This allows for greater flexibility in tracking and identifying steel products, and can help improve efficiency and accuracy in manufacturing processes.

Overall, machine-made steel code products can provide significant benefits to the steel industry, improving efficiency, accuracy, and quality control throughout the manufacturing process.

Machine-typed steel code refers to a type of identification or marking system used in the steel industry to label and track steel products. The code is typically stamped or etched onto a metal plate or tag, which is then attached to the steel product.

Machine-typed steel codes may include a wide range of information, including lot numbers, production dates, material specifications, and other identifying markers. The codes are typically alphanumeric, and can be read and interpreted using specialized equipment such as scanners or handheld device.

These codes can be important for ensuring the quality and traceability of steel products throughout the manufacturing process. By tracking the production history and specifications of a particular steel product, manufacturers can ensure that it meets the necessary standards and requirements for its intended use.

When implementing a machine-typed steel code system, it is important to consider factors such as readability, durability, and compatibility with existing equipment and processes. Working with an experienced metal stamp manufacturer can help ensure that the final product meets the needs and specifications of the customer.

Overall, machine-typed steel codes can be a valuable tool for the steel industry, helping to improve efficiency, accuracy, and quality control throughout the manufacturing process.