Curved Stamp

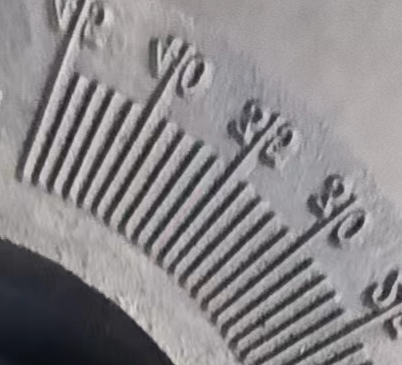

A curved stamp is a specialized metal stamp designed to fit onto and conform to curved or irregular surfaces. These stamps can be used to create permanent, stamped impressions onto materials such as pipes, tubes, or other cylindrical shapes.

Curved stamps are typically custom-made to fit the specific curvature of the material being stamped. They may feature a curved shape that matches the diameter of the pipe or tube, or they may be designed with a flexible shank that allows them to bend and conform to the shape of the material.

When selecting a curved stamp, it is important to consider factors such as durability, accuracy, and ease of use. A quality stamp will be made from high-quality materials, such as hardened steel, and will provide consistent, clear impressions with minimal effort. The stamp should also be designed to accurately reproduce the details and intricacies of the design being stamped.

Overall, a curved stamp can be a valuable tool for industries that rely on stamped identification and labeling on curved or irregularly shaped materials. Working with an experienced metal stamp manufacturer can help ensure that the final product meets the needs and specifications of the customer.

These are just a few examples of the types of product details that may be relevant for curved stamps. Ultimately, the specific requirements will depend on the needs of the customer and the intended use of the stamp. A reputable metal stamp manufacturer will work closely with their customers to understand their needs and provide high-quality custom stamped products that meet those needs.

The specific details of a curved stamp can vary depending on the application and the materials being stamped. However, some common product details that may be important for curved stamps include:

Material: The type of material used to make the stamp, which is typically a high-quality steel or other durable metal.

Stamp design: The specific design or artwork to be stamped onto the curved surface, which can range from simple lettering and numbering to more complex designs.

Curvature: The curvature of the stamp, which will be custom designed to match the diameter and shape of the material being stamped.

Shank flexibility: The flexibility of the shank, which allows the stamp to bend and conform to the shape of the material being stamped.

Hardness: The hardness of the stamp material, which is typically measured on the Rockwell scale and can influence the durability and lifespan of the stamp.

Quantity: The desired quantity of stamps, which can affect the manufacturing process and cost per unit.

Delivery requirements: Any special delivery or packaging requirements for the stamps, such as expedited shipping or custom packaging options.